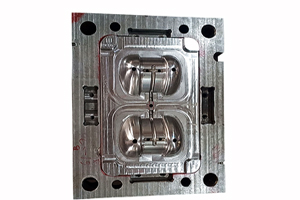

Product Display

Injection safety shoe toe plastic toe

Type: Plastic mould

Description:

Product name: plastic safety toe

Material: PC transparent

Finished appearance: smooth surface without burrs or sharp corners

Inner length: 34-40mm

Crimping width: <10mm

Static pressure resistance: Safety shoes are resistant to static pressure 15KN/Protective shoes are resistant to static pressure 10KN

Plastic PC toe-new environmental protection and safety toe

main feature

1.Acid and alkali corrosion resistance;

2.Crash resistance, impact resistance above 200 joules

3.Oil resistant

4.Lightweight, 1/2 to 1/3 of the weight of the steel head;

5.PC transparent material, safe and environmentally friendly;

6.The development speed is fast, and the mold development time is generally 7 days Main advantages: high impact strength, good creep resistance and dimensional stability, heat resistance, transparency, good dielectric properties, low water absorption, non-toxic

[/av_textblock]

[av_hr class='custom' height='50' shadow='no-shadow' position='center' custom_border='av-border-thin' custom_width='1310px' custom_border_color='#000000' custom_margin_top='0' custom_margin_bottom='0' icon_select='no' custom_icon_color='' icon='ue891' font='entypo-fontello' av_uid='av-jzcbmusk' admin_preview_bg='']

[av_button label='Get a Quote Now' link='manually,https://jk-mold.com/contact-jk/' link_target='_blank' size='medium' position='left' label_display='' icon_select='yes' icon_hover='aviaTBicon_hover' icon='ue805' font='entypo-fontello' color='black' custom_bg='#444444' custom_font='#ffffff' av_uid='av-4cmz75' admin_preview_bg='']

[av_hr class='custom' height='50' shadow='no-shadow' position='center' custom_border='av-border-thin' custom_width='1310px' custom_border_color='#000000' custom_margin_top='0' custom_margin_bottom='0' icon_select='no' custom_icon_color='' icon='ue891' font='entypo-fontello' av_uid='av-jzcbmusk' admin_preview_bg='']

[av_textblock size='' font_color='custom' color='#000000' av-medium-font-size='' av-small-font-size='' av-mini-font-size='' av_uid='av-6kskdd' admin_preview_bg='']

Share this entry: