Product Display

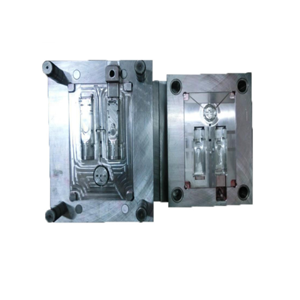

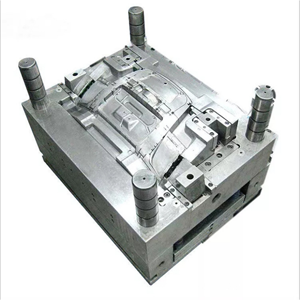

Intelligent electric oral irrigator plastic mold

Type: Plastic mould

Description:

The intelligent electric oral irrigator shell plastic mold is a single-color plastic mold carefully crafted by Jiekai. The injection product has no shrinkage, flash, or defects.

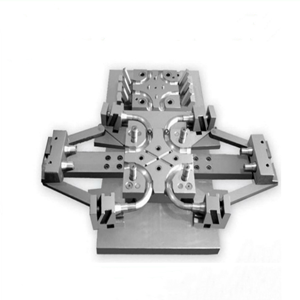

Jiekai Industrial is a high-quality plastic mold manufacturing and processing manufacturer for exterior parts. For 18 years, it has focused on the production of various single/two-color plastic molds. Single-color plastic molds are sampled in 9 days, and two-color plastic molds are sampled in 18 days. The processing accuracy is 0.005MM. Plastic molds include a series of services from mold design-mold manufacturing-raw materials-injection molding-production-processing.

Share this entry: