Product Display

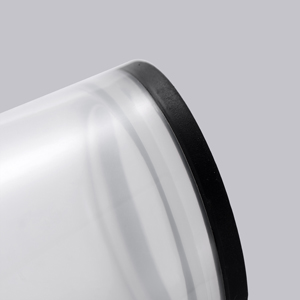

cup bowl two shot mold

Type: Plastic mould

Description:

cup bowl two shot mold, made of TPE/PP

Bottom two shot molding TPE,since body is PP,it is very difficult to control shrinkage,which caused big sealing issues.

TPE always over molding of PP body, we have to re-design the PP body and make the bottom stronger

Pin-point gate,3 points for TPE, 1 for PP body.

Hardened S136 HRC48-52 and LKM mold base

We do first trial mold In 22 days,and start production after 35 days

Share this entry: