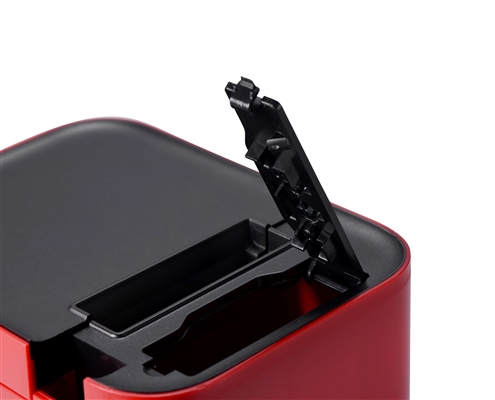

Product Display

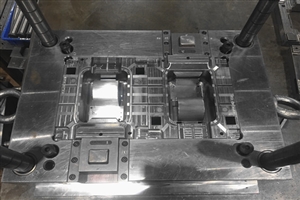

Take out printer plastic housing mold

Type: Plastic mould

Description:

Description: Take out printer plastic housing mold

The printer housing series has 6 sets mould

We do first trial mold In 18 days,and start production after 45 days

Molding circle time is 65s

more cooling channels and venting slot required Main body has 4 side sliders, cavity lifter, the slider split line is 0.02mm required, assembly miss match is less than 0.03mm

Share this entry: